Harp Renewables

Where electrical engineering meets biotechnology.

Harp Renewables combines electrical engineering expertise with renewable and proprietary biotechnology to provide a better, cleaner, and more sustainable alternative to traditional waste disposal. With multiple sizes to choose from, organizations of all sizes can benefit from the power of Harp Renewables Bio-Digesters.

Harp Renewable’s Bio-Digester’s on-board processor controls the internal parameters, such as temperature, pH, moisture, oxidation, and surface area, for optimum organic breakdown. This incredible technology achieves a decomposition phase within 24 hours.

Reducing weight and volume of organic waste by up to 85%, sequestering carbon & better nutrient retention, lowering emissions, and providing a high-quality soil end-product are just a few of the primary benefits of this technology.

Another major benefit is the output of these Bio-Digesters. When organic materials enter the digester feed, Harp’s accelerated thermal process minimizes the volatilization of carbon to CO2eq. Using a proprietary enzyme, Harp Renewables Bio-Digesters ensure that the biological pathway for carbon is mineralized, which traps more carbon in the substrate.

With 100% more organic carbon locked within the end-product, the Harp Renewable end-product contains 48% Total Organic Carbon, whereas most other soil products have between 18-30%. Reducing carbon emissions that come from traditional disposal and decomposition processes.

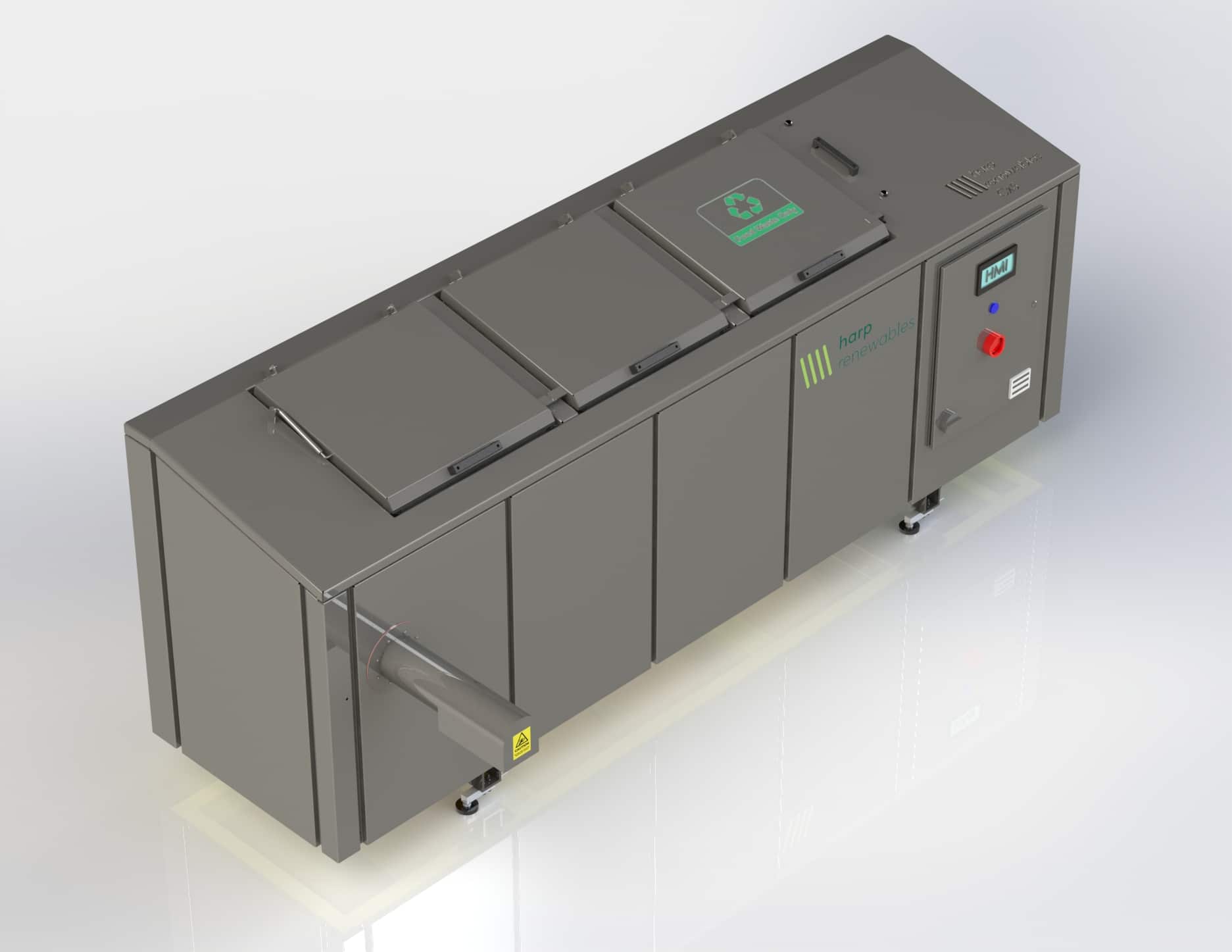

CX1 Bio-Digester

The smallest bio-digester that has the ability to digest up to 1000 liters a week. Making it the perfect choice for schools, cafes, or restaurants.

CX2 Bio-Digester

Recently remodeled, the CX2 has numerous new features. It has the ability to digest up to 2,000 liters a week and is suitable for recycling centers, large restaurants, or Universities.

CX5 Bio-Digester

With an astounding ability to digest up to 5,000 liters per week, the CX5 gives clients flexibility when discarding organic waste. This unit is ideal for pharmaceutical companies, hospitals, and large school institutions.

-

Organic Waste is Added to the Bio-Digester

-

Material is Heated

Bio-Digester's core temperature is monitored and maintained at 72.C and enzymes begin to break down materials.

-

Process is Complete in 24 Hours

Once the process is complete, safe materials are augured out of the Bio-Digester